Understanding the Role of CNC Lathe Turning Parts Manufacturers

Introduction to CNC Turning Parts

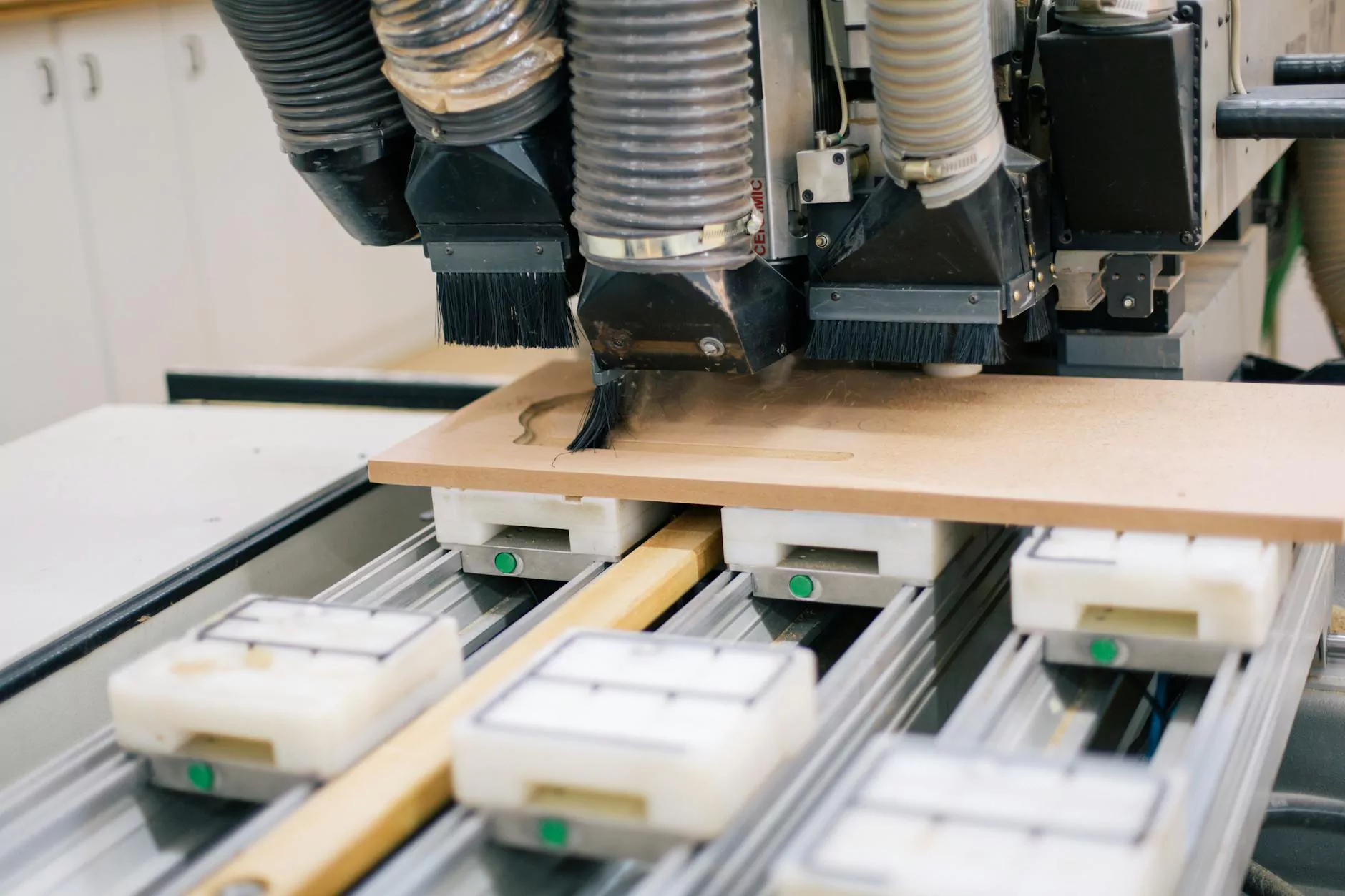

The world of manufacturing is constantly evolving, and CNC lathe turning parts manufacturers are at the forefront of this evolution. Not only do they play a crucial role in the production of precision components, but they also significantly impact various industries including automotive, aerospace, and electronics. By harnessing advanced technology and skilled craftsmanship, these manufacturers ensure the delivery of high-quality products that meet stringent standards.

What are CNC Lathe Turning Parts?

CNC (Computer Numerical Control) lathes are machines that rotate a workpiece about an axis to perform various operations, such as cutting, sanding, drilling, and deforming materials. The result is CNC lathe turning parts, which are vital for the assembly of machinery and equipment across a multitude of sectors. The parts created by these machines are known for their precision, repeatability, and high-quality finishes.

The Importance of Quality in Manufacturing

Quality is a cornerstone in manufacturing, particularly when it comes to CNC lathe turning parts manufacturers. The use of high-grade materials, advanced machinery, and rigorous quality checks ensures that every component produced is reliable and resilient. This commitment to quality not only enhances product lifespan but also minimizes the risk of failures, which can lead to costly downtimes and repairs.

Industries Benefitting from CNC Lathe Turning Parts

Several industries leverage the expertise of CNC lathe turning parts manufacturers. Here are the most prominent sectors that benefit:

- Automotive Industry: Components like engine parts, transmission housings, and suspension pieces require exceptional accuracy.

- Aerospace Sector: Lightweight, robust parts such as turbine blades and landing gear are crucial for aeronautical applications.

- Medical Equipment: Precision components such as surgical instruments and implants must adhere to strict regulatory standards.

- Electronics: From casings to connectors, the electronics industry relies on high-precision turning parts for functionality.

Advantages of CNC Machining Over Traditional Methods

Understanding the advantages of CNC machining over traditional manufacturing methods helps justify the preference for CNC lathe turning parts manufacturers. Some key advantages include:

- Precision: CNC lathes can create complex geometries with extreme accuracy, which is often unattainable with manual machining.

- Consistency: Automated processes guarantee uniform quality, reducing variations across batches.

- Efficiency: CNC machines operate for longer periods without fatigue, increasing production rates and reducing lead times.

- Flexibility: Quick reprogramming allows manufacturers to switch between different projects or parts easily.

Choosing the Right CNC Lathe Turning Parts Manufacturer

Selecting a reliable manufacturer is essential for obtaining quality CNC turning parts. Here are several factors to consider:

1. Experience and Expertise

Look for manufacturers with extensive experience in CNC machining. Their expertise often translates to better quality and more innovative solutions.

2. Technology and Equipment

The quality of machinery and technology used by the manufacturer can significantly impact the final product. Ensure they use the latest CNC technology for optimal precision.

3. Quality Control Measures

Inquire about the quality control protocols in place. A good manufacturer will have rigorous testing and inspection processes to ensure that every part meets high standards.

4. Customer Reviews and Testimonials

Reviewing feedback from previous customers can provide insight into the manufacturer's reliability and product quality. Look for positive testimonials and case studies that reflect their capabilities.

5. Competitive Pricing

While price shouldn’t be the sole deciding factor, it’s important to ensure that the cost is justified based on the quality of service and products offered. Get quotes from multiple suppliers for comparative analysis.

Technological Innovations in CNC Turning

As technology evolves, CNC lathe turning parts manufacturers are increasingly adopting innovations that enhance their manufacturing processes. Here are some notable advancements:

- Automation: The integration of robotics streamlines operations, allowing for unmanned production runs, which significantly increases efficiency.

- 3D Printing Integration: Some manufacturers are beginning to incorporate additive manufacturing alongside CNC machining, enabling more complex part designs.

- IoT Connectivity: Smart machining processes allow for real-time monitoring and adjustments, optimizing performance and reducing waste.

- Advanced Materials: The development of new materials tailored for CNC processing enhances product performance and expands application possibilities.

Environmental Considerations in CNC Manufacturing

As industries move towards more sustainable practices, it’s vital for CNC lathe turning parts manufacturers to adopt environmentally friendly practices. Some strategies include:

- Recycling Best Practices: Efficient recycling of leftover materials and used machining fluids minimizes waste.

- Energy Efficiency: Investing in energy-efficient machinery helps reduce the carbon footprint of manufacturing operations.

- Use of Biodegradable Coolants: Environmentally friendly cutting fluids can replace traditional options, which are often hazardous.

- Lean Manufacturing: Implementing lean techniques reduces waste and increases value within the manufacturing process.

Future Trends in CNC Turning Parts Manufacturing

The landscape of CNC lathe turning parts manufacturing is continuously evolving. Future trends to watch for include:

- Increased Customization: As customer demands shift towards personalized products, manufacturers will increasingly need to offer tailored solutions.

- Smarter Machines: The move towards AI-driven CNC machines can enhance decision-making, enabling faster and more precise operations.

- Global Supply Chains: Manufacturers will need to adapt to fluctuations in global supply chains, possibly involving local sourcing strategies.

- Resilience Against Disruptions: Building robust operational frameworks to withstand future market disruptions will become paramount.

Conclusion

In conclusion, the role of CNC lathe turning parts manufacturers is paramount in delivering quality parts that power modern industries. By understanding the advantages of CNC machining, the importance of selecting the right manufacturer, and the latest technological advancements, businesses can greatly enhance their operations. As we look to the future, staying informed about innovations and trends will equip industries with the tools needed to adapt and thrive.

For more information, visit us at DeepMould.net.